- 09 oktober 2018

- Door Astrid Baxter

- | 6 min. leestijd

Seeing simplicity in complexity

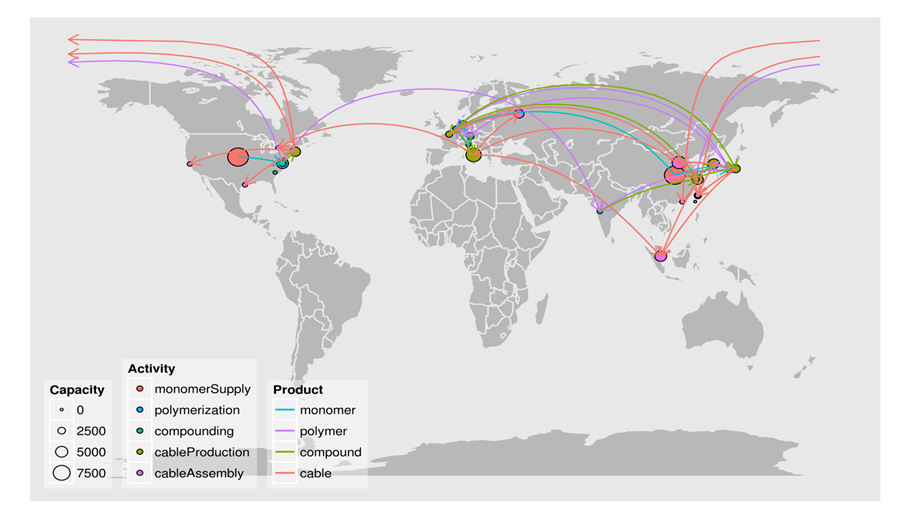

Climate change drives large scale energy transition. Governments impose increasingly stringent regulations on what manufacturers can do. Demographic shifts disrupt societies around the world. All this means that manufacturers must learn how to manage price volatility in their raw materials, incorporate greater flexibility into their operations, and make sure their logistical operations are resilient to sudden changes.

Sorry, dit is een premium artikel

Dit artikel is exclusief beschikbaar voor abonnees. Abonneer je nu en krijg toegang tot alle artikels.

Ontdek onze abonnementsformules